PHOTO.CAT

Unit

Removing complex pollutants from used textile production water to save resources and energy, and protect the local environment

Overview

The textile industry relies on water-intensive processes

In particular, water is used for cleaning raw materials and as part of the dyeing process

Production relies on many different substances, such as synthetic dyes, solvents, resins, caustic soda and bleach. These substances can end up in used water streams and are difficult to treat.

Project Ô has developed the PHOTO.CAT unit to treat water used in textile production

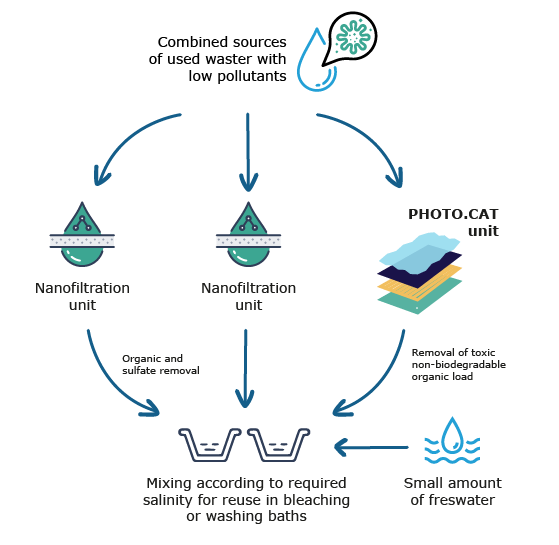

It will remove dyes from used water and it can help increase the amount of water that can be reused in a textile production factory

By using PHOTO.CAT and nanofiltration technologies, textile producers have control over the levels of sodium sulphate in the water that is reused in the dyeing process.

Solution

PHOTO.CAT is a water filtration photocatalytic unit

It can be used at any textile production factory

PHOTO.CAT unit benefits include:

A PHOTO.CAT unit was first installed in Croatia at a textile production factory

Galeb d.d. is a textile company in Croatia

They are building a new water treatment plant as part of their factory development. Their goal is to achieve high standards of water management using a circular water economy approach.