Croatia

Supporting the textile industry to allow water and resources to be reused

Challenge

We need water to survive

But every day, finite freshwater resources are used and discarded through unsustainable industrial production.

It is especially important to reduce the impact of water-intensive industries, such as clothing. For example, on average, it takes 2,700 liters of water to make a simple cotton t-shirt. That’s enough water for one person to drink for 900 days. Also, the water used for clothing production is contaminated with chemicals that harm the natural environment, if left untreated.

Galeb, a clothing factory in Croatia, is working to increase the reuse of finite water resources by building its own water treatment plant.

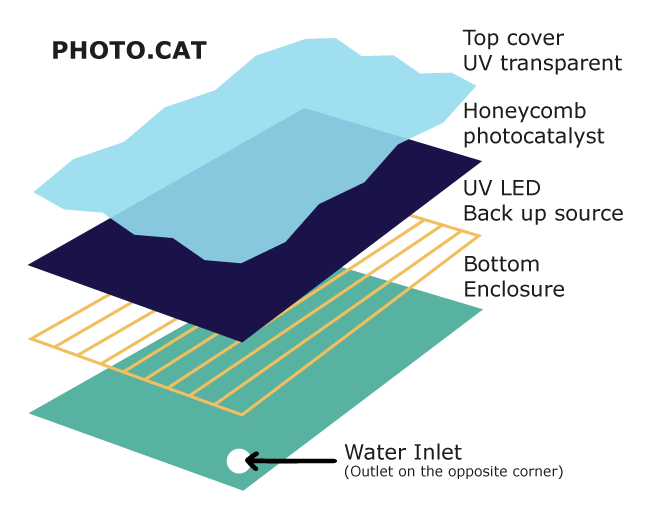

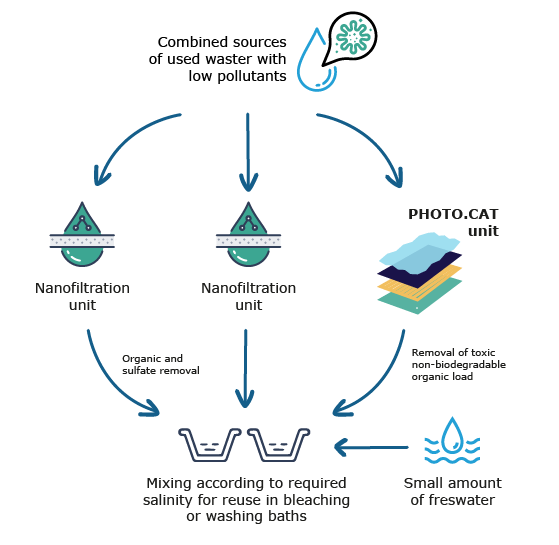

Project Ô has developed the PHOTO.CAT unit to become part of their new water treatment plant

It will remove harmful chemicals and organic pollutants and recover salts from the water.

The treatment process is designed to automatically mix different streams of treated water to ensure the right salt levels and temperatures for making clothing materials.

These targeted treatments enable the factory’s immediate reuse of the water, and also boost energy efficiency because the treated water is already optimised for clothing production.

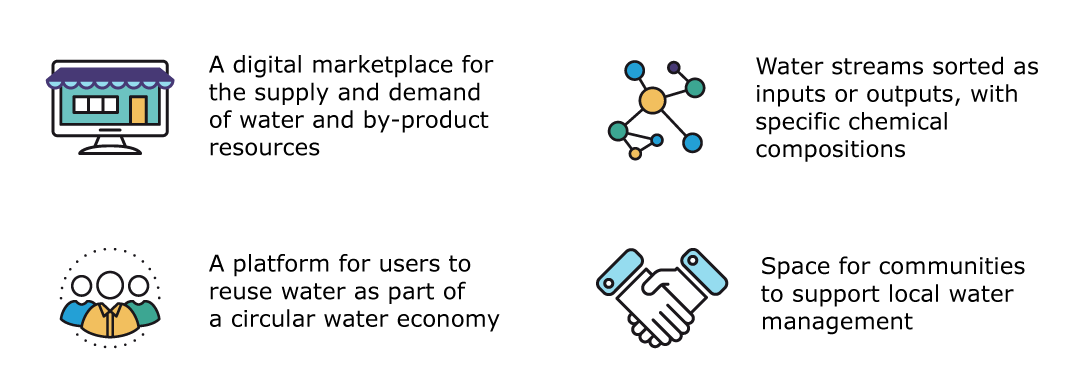

Project Ô has developed a Circular Economy Platform (CEP) to expand business opportunities

CEP includes a tech-selection box

This allows businesses to evaluate which of the Project Ô technology modules has the greatest economic and operational sustainability benefits for their water treatment needs. It also gives businesses the ability to assess if any local collaboration opportunities are available.

Background

Omiš is a small Croatian town about 26 kilometres south-east of Split

This coastal town has a thriving tourist industry and has been given a Natura 2000 designation due to its environmental importance

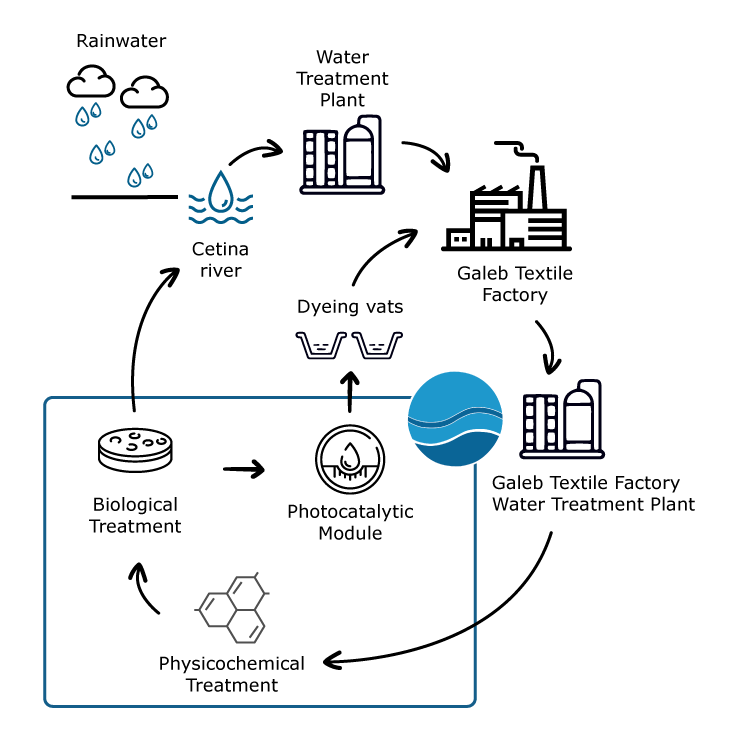

Galeb are an established textile company who is building a new factory in Omiš with its own water treatment plant. One aim of the new water treatment plant is to allow Galeb to treat and reuse their own used water. This would reduce the need for fresh input water and allow recovery of dyeing salts for reuse, as well as being more cost-effective and a sustainable use of resources.

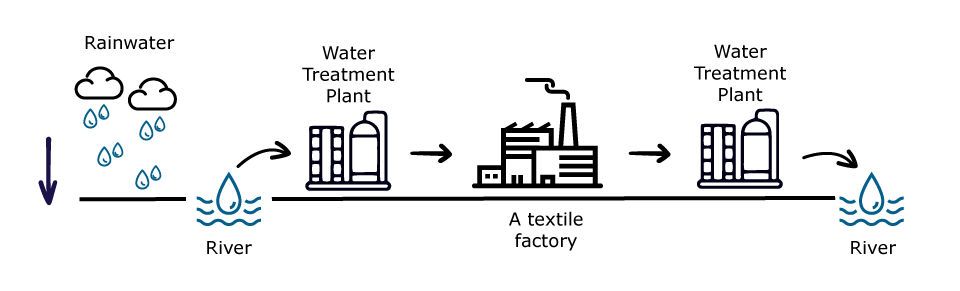

It will improve on the following more commonly

applied linear economy approach

Project Ô has developed PHOTO.CAT technology. It is designed to remove these specialist industrial substances, including dyes. Treatment partially removes dissolved salt from the used water, which makes it ideal for immediate reuse in the dyeing process. As dyeing is one of the most water-intensive steps, this has a huge impact on reducing resource use as well as preventing the release of salty water into the environment. CEP will also provide possible opportunities for local collaborations and new business.

By treating their own specialist used water, Galeb can reduce their costs, energy and resource consumption, and protect their local environment.

Circular Water Economy

Project Ô technologies increase the factory’s sustainability and efficiency because more water can be reused while requiring less energy. This reduces demands on finite freshwater resources and power supplies.

Project Ô technologies have helped close the loop on water use in textile production in Omiš in Croatia

And this leads to other benefits too...

Solution

PHOTO.CAT is a water filtration unit that can treat chemicals used in textile production

It aids water reuse as the process does not affect dissolved salts

The combination with nanofiltration technology allows dye baths to be supplied with reused water that still contains the salts and temperature needed for dyeing. Reuse lowers operating costs and reduces the environmental impact. The benefits of the PHOTO.CAT unit include:

CEP is designed to allow businesses to participate in a circular water economy

The purpose of CEP is to allow for the local trade of water and by-products between different water users involved in water treatment activities